Before the demo started, Mick Denton asked those who had ordered club shirts to collect them over the course of the evening.

We once again had a double act tonight with Chris Harkin and Geoff Warr making two very different and unrelated items.

Chris began by showing us his very simple – but effective – jig for making pendants and also showed us Geoff’s far posher equivalent.

Chris’s jig is a simple piece of board with a recess to suit the pendant being made, and a slot along much of its length to allow slight variations in size. This home-made chuck is held in a scroll chuck, with the sides angled to suit the scroll chuck jaws e.g. straight or dovetail. Two grooves cut in each side allow the chuck jaws to be positioned accurately for on-centre or off-centre turning.

To make the pendant, he mounted a piece of yew about 125mm long x 75mm square between centres and proceeded to turn it to a nominal 50mm round.

After this he put a tenon on one end and mounted it in the scroll chuck. At this point he found a split in the wood so he parted off the affected portion, still leaving plenty of wood for the next stage.

Chris now carefully reduced the diameter of the blank to suit the recess in his jig. It must not be undersize so he measured the diameter using vernier calipers with the pointed tips ground off to prevent a catch.

Once the diameter was confirmed as correct, he parted off a couple of discs about 3 to 4mm thick for making the pendants.

In order to mount the jig on the lathe he used a scroll chuck with just two deep jaws fitted. Aligning the edges of the jaws with the centralising grooves, he held it in place, inserted a disc in the jig recess and then tightened up the scroll chuck to hold the disc securely in place.

He cleaned up the surface (the back) of the pendant disc with a gouge and abrasives then reversed it into the recess to repeat the process with the front side. Now for the fun bit, Chris remounted the jig and pendant in the scroll chuck, this time locating the jaws into the “off centre” grooves.

He drilled a hole through the centre and added a few grooves for decoration, and then sanded it down to a fine finish.

Finally, he removed the pendant from the jig and drilled a small hole for the clasp, before fitting the clasp and necklace to finish the job. He buys the clasps and necklaces from eBay or Amazon for pennies, so the completed pendant is very cheap to make, using as it does very little wood. A selection of Chris’s pendants are shown below.

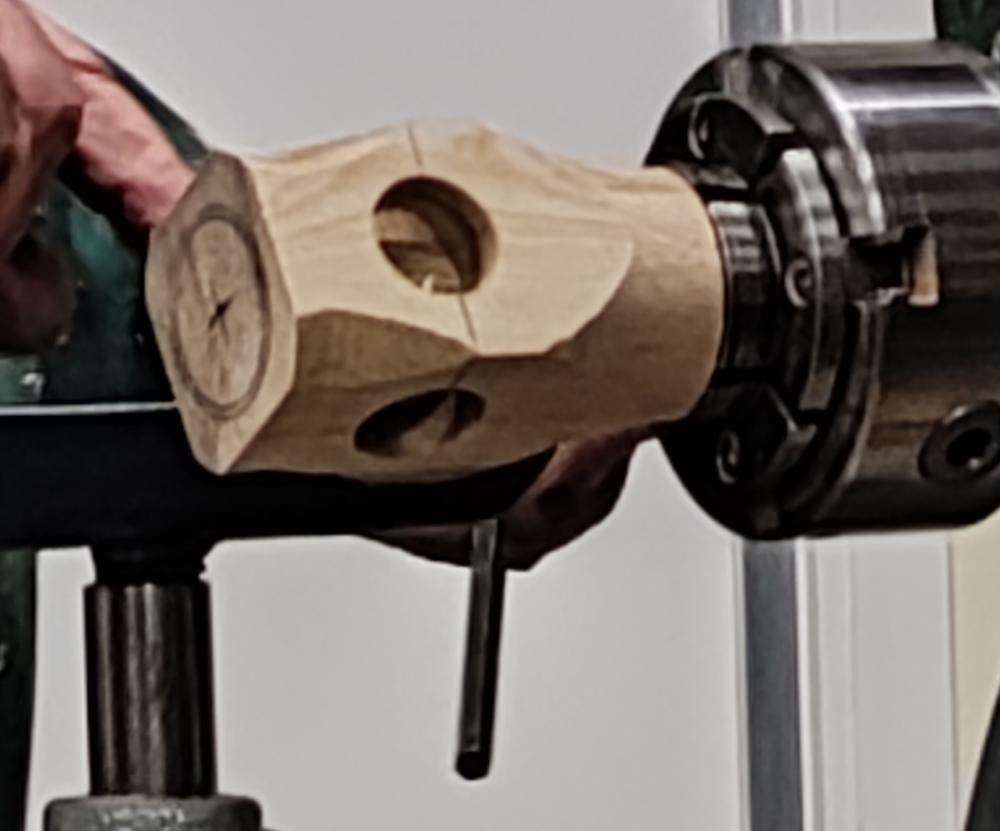

Geoff decided to stick with the approaching season and made an attractive Christmas lamp with an LED tea light. He started with a block of wood that had three holes drilled in it to allow the light to escape. The fourth side will be placed to the back so can act as a reflector.

LED tea lights can be bought very cheaply from the usual online outlets or from Hobbycraft.

With the blank between centres, he put a chucking tenon on one end and turned it to round, taking care as there was a lot of air in way of the holes.

The basic dimensions of the lamp are shown on the annotated blocks of wood below.

Next, holding the blank in the chuck, he used a 38mm Forstner to drill in to the depth of the drill, taking it past the three holes. He then used a 1 3/8” bit to make a shoulder for the tealight to sit upon.

Once done he cleaned up the inside with a spindle gouge and abrasives (using a stick to avoid putting his fingers inside!).

Geoff next shaped the outside and added a few detail lines.

After this he sanded and applied a wax finish (he would usually apply a lacquer but volatile substances mustn’t be used in the hall for safety reasons).

Reversing the lamp onto a jam chuck, he held it in place with the tailstock and shaped the top end before sanding it and cutting off the end. The ghost of the jam chuck can be seen in the following picture.

A quick hand sand of the nub was followed by drilling a small hole through the top for a hanging cord or wire.

The competition table had an interesting variety this month.

1st place was a hollow “pumpkin” with threaded lid by Gerald Hubbard – deserving of two pictures!.

2nd place was a set of yew natural edge lidded pots by Mick Denton.

3rd place went to a bowl made from a cotoneaster root ball by Arthur Ellis. Rock hard apparently!