Before the demo started, we were told that the club challenge for Daventry Woodworks next year is to be a teaset – teapot, cups, saucers, plates and accessories. This gives plenty of scope for interpretation and opportunity for lots of people to take part. Should be fun!

We had a double act tonight with Mick Denton and Viv Harvey tasked with making the same item in whichever way they thought best. We, the audience, were not privileged to be told what they were making so we just had to be patient and try to figure it out from the two quite different approaches on show.

Mick started off with a cube of oak about 100mm on a side, mounted on a screwchuck.

This he proceeded to bring to round before using a bowl gouge to shape it to a rounded cone with a tenon on the end.

After sanding it he reversed it onto the chuck and centred it before tightening the chuck for a secure hold.

Using a bowl gouge and a carbide tipped hollowing tool Mick hollowed it out and then drilled a hole through the bottom.

After a quick sanding, he took it off the chuck and dribbled some superglue into a crack that had appeared in the wood.

Another block of wood was mounted between centres, rounded, and drilled through before opening up further. Mick used a 10mm parting tool to size the edges to suit the tenon on the larger piece of wood and then drilled all the way through before reversing it.

After adding some detailing and sanding it, he parted it off and then glued the two pieces together with a dab of superglue to hold everything in place while the PVA glue set.

The picture shows the one that Mick made today as well as an earlier practice piece. Starting to get an idea of what it is now?

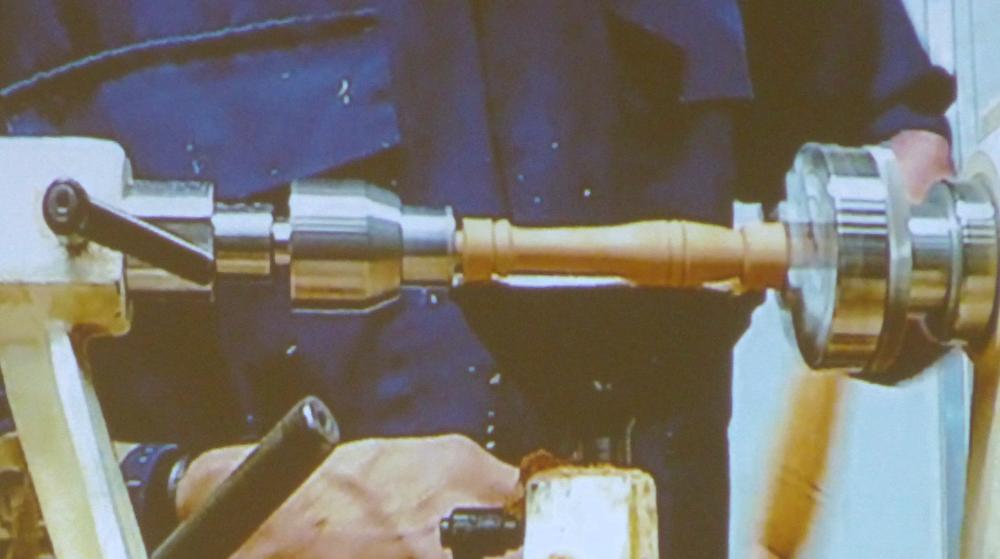

Viv started off with a block of sapele about 150mm long x 110mm square, mounted between centres.

Bringing it to round with a spindle roughing gouge, he then put a chucking tenon on each end with a bedan/parting tool.

Moving to a smaller piece of wood about 150mm long x 65mm square, he brought it to round with a spindle roughing gouge before drilling out the end and hollowing the opening out with a spindle gouge.

He then brought up the tailstock for support and shaped the outside; all finished off with acrylic sanding sealer and beeswax before parting it (what exactly???) off.

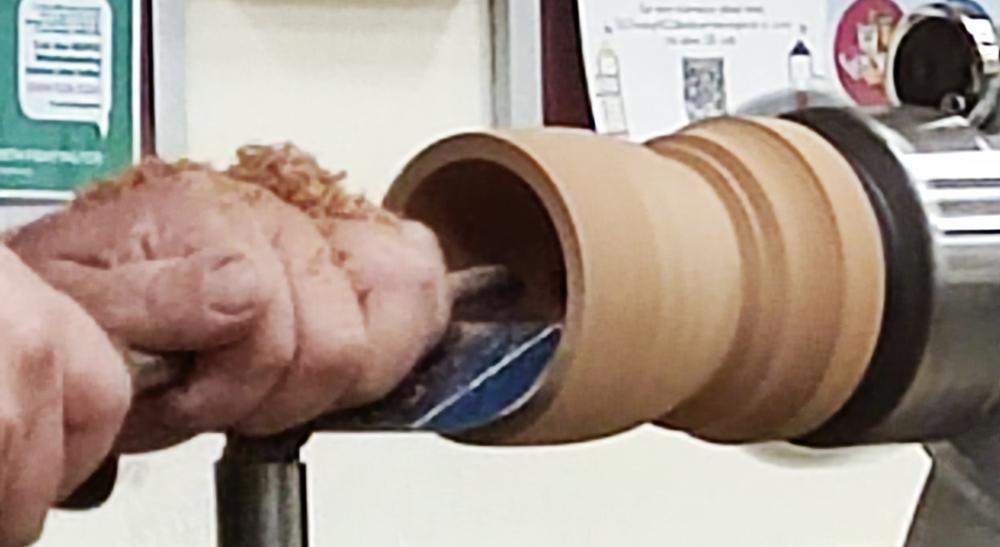

The larger piece of wood was now mounted into the chuck, drilled out and reversed. The now redundant chucking tenon was removed with a parting tool and shaping of the exterior began.

With the shape established, Viv hollowed out the inside with a spindle gouge and then used a scraper to get a clean finish, following up with some abrasive on a stick to avoid catching his fingers.

For aesthetics, he added some detailing and wire-burn lines.

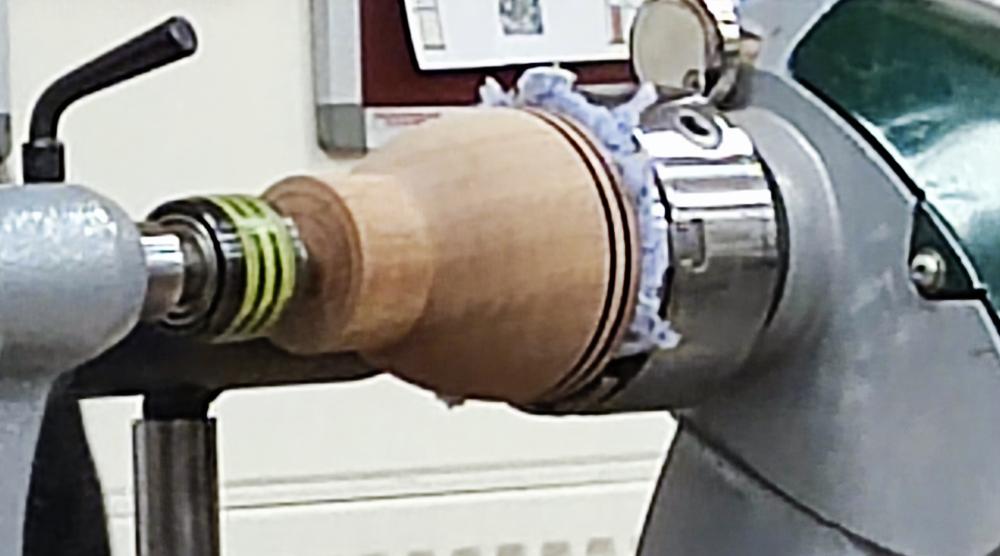

Next, he parted if off and reversed it onto the chuck jaws, using some paper to to protect it from damage as the tailstock was brought up to hold it in place.

With it securely held, Viv finessed the tenon size to suit the other component, applied superglue, and pushed the two items together with the tailstock.

He once again used acrylic sanding sealer and beeswax as a finish and then buffed it up.

So what was this all about?

The picture shows Viv’s offering from an angle that may help you to figure out that these are a pair of funnels, something that we’ve all made at one time or another!